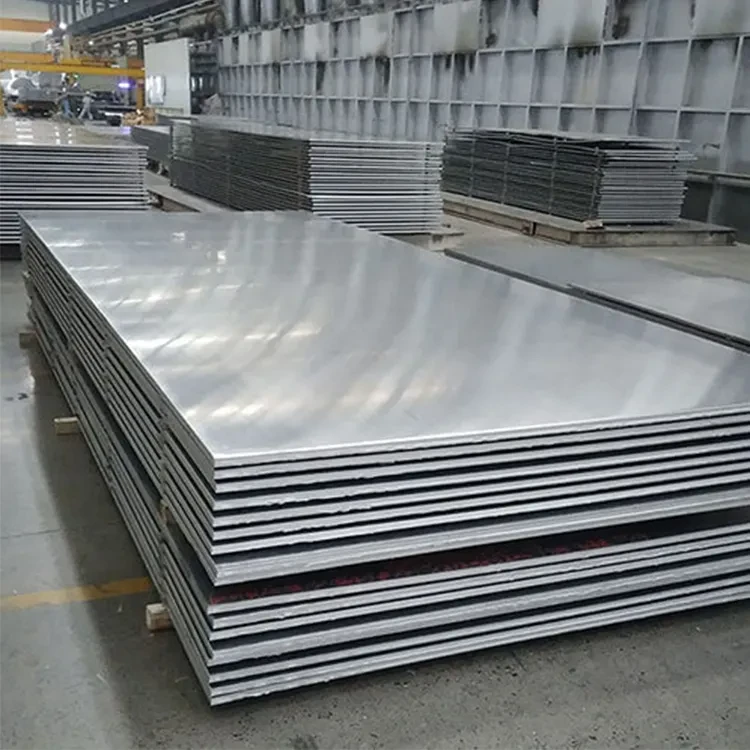

Standard Specification:

| Product Name | Stainless steel sheet / plate |

| Technique | Hot rolled or cold drawing |

| Thickness | Cold rolled 0.3 to 3mm |

| Hot rolled 3mm to 60mm or as customer’s request | |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm or as customer’s needs |

| Length | 2000mm-6000mm or as customer request |

| Standard | ASTM JIS AISI GB DIN EN |

| Surface Finished | 2B/BA/NO.4/6K/8K/GOLDEN MIRROR/HL/NO.1 etc. |

| Certification | SGS, BV, IQI, TUV, ISO, etc. |

| Grade(ASTM UNS) | 201 202 301 304 304L 321 316 316L 317L 347H 309S 310S 904L |

| S32205 2507 254SMOS 32760 253MA N08926 etc. | |

| Grade (EN) | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404 ,1.4571, 1.4438, 1.4539, 1.4547, |

| 1.4529, 1.4562, 1.4410, 1.4878, 1.4845, 1.4828, 1.4876,2.4858, 2.4819 | |

| Brand Name | TISCO, BAOSTEEL, POSCO(ZPSS), POSCO, etc. |

| Delivery time | Within 7-10 Working Days |

| Price Terms | CIF CFR FOB EX-WORK |

| Export Packing | Waterproof Paper, Steel Strip Packed and other Standard Export |

| Seaworthy Package, or customized package | |

| Payment Terms | T/T or L/C |

Chemical Composition:

| Stainless Steel Composition Chart, Percentage (%) | |||||||||

| Grade | C, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Si, ≤ | Cr | Ni | Mo | N, ≤ |

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | – | – |

| 304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | – | – |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | – |

| 316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | – |

| 321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | – | 0.1 |

| 201 | 0.15 | 5.50-7.50 | 0.06 | 0.03 | 1 | 16.0-18.0 | 3.5-5.5 | – | 0.25 |

| 301 | 0.15 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 6.0-8.0 | – | 0.1 |

| 302 | 0.15 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 8.0-10.0 | – | 0.1 |

| 303 | 0.15 | 2 | 0.2 | ≥0.15 | 1 | 17.0-19.0 | 8.0-10.0 | – | – |

| 305 | 0.12 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 11.0-13.0 | – | – |

| 308 | 0.08 | 2 | 0.045 | 0.03 | 1 | 19.0-21.0 | 10.0-12.0 | – | – |

| 309S | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | – | – |

| 310S | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.0-26.0 | 19.0-22.0 | – | – |

| 310H | 0.04-0.10 | 2 | 0.045 | 0.03 | 0.75 | 24.0-26.0 | 19.0-22.0 | – | – |

| 316Ti | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.1 |

| 317L | 0.03 | 2 | 0.045 | 0.03 | 0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | 0.1 |

| 321H | 0.04-0.10 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 9.0-12.0 | – | – |

| 347H | 0.04-0.10 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 9.0-13.0 | – | – |

| 348H | 0.04-0.10 | 2 | 0.045 | 0.03 | 0.75 | 17.0-19.0 | 9.0-13.0 | – | – |

| 2205 | 0.03 | 2 | 0.03 | 0.02 | 1 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 |

| 2507 | 0.03 | 1.2 | 0.035 | 0.02 | 0.8 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 |

| 410 | 0.08-0.15 | 1 | 0.04 | 0.03 | 1 | 11.5-13.5 | – | – | – |

| 420 | 0.15, ≥ | 1 | 0.04 | 0.03 | 1 | 12.0-14.0 | – | – | – |

| 430 | 0.12 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | – | – | – |

| 440A | 0.60-0.75 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | – | ≤0.75 | – |

| 440B | 0.75-0.95 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | – | ≤0.75 | – |

| 440C | 0.95-1.20 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | – | ≤0.75 | – |

| 440F | 0.95-1.20 | 1.25 | 0.06 | 0.15 | 1 | 16.0-18.0 | 0.5 | – | – |

| 800H | 0.05-0.10 | 1.5 | 0.045 | 0.015 | 1 | 19.0-23.0 | 30.0-35.0 | – | – |

| 904L | 0.02 | 2 | 0.045 | 0.035 | 1 | 19.0-23.0 | 23.0-28.0 | 4.00-5.00 | 0.1 |

| 15-5 PH | 0.07 | 1 | 0.04 | 0.03 | 1 | 14.0-15.5 | 3.5-5.5 | – | – |

| 17-4 PH | 0.07 | 1 | 0.04 | 0.03 | 1 | 15.5-17.5 | 3.0-5.0 | – | – |

| 17-7 PH | 0.09 | 1 | 0.04 | 0.04 | 1 | 16.0-18.0 | 6.5-7.75 | – | – |

Surface Treatment:

Advantages:

1. High-quality protection grade,

2. High strength and corrosion resistance, strong oxidation resistance.

3. General corrosion and chloride pitting resistance.

4. Higher creep, stress-to-rupture and tensile strength at elevated temperatures.

Package:

Reviews

There are no reviews yet.